The American Society of Agricultural and Biological Engineering (ASABE) has honored two groundbreaking innovations from CLAAS with AE50 Awards: the JAGUAR 1000 forage harvester series and the ORBIS 10500 corn header. The official award ceremony will take place in February 2026 at the ASABE Agricultural Equipment Technology Conference in Louisville, Kentucky.

January 19, 2026 — “These two AE50 awards confirm what our customers already know: CLAAS continues to set standards in terms of performance, efficiency, and intelligent machine design for the harvesting of forage crops,” explains Dennis Ogle, Sales Manager for Self-Propelled Harvesting Technology at CLAAS of America. “Both the JAGUAR 1000 series and the ORBIS 10500 were developed in close collaboration with farmers and contractors, with a focus on real productivity gains and ease of use with a high degree of automation.”

JAGUAR 1000: Top performance in new dimensions

The four models in the JAGUAR 1000 series represent a new generation of forage harvesters, based on more than 50 years of experience in the development and manufacture of self-propelled forage harvesters. With engine outputs of up to 1,110 hp, the development focus was particularly on a well-thought-out, future-proof overall concept for optimum efficiency and maximum throughput capacity – confirmed, among other things, by the impressive official Guinness World Record for forage harvesting. The convincing arguments include the widest crop flow on the market, fully hydraulic pre-compression, uncompromising and homogeneous chopping quality, the large 310 mm diameter corncracker for optimum grain release, the drive concept with two independent variable front attachments for newly developed, high-throughput PICK UP and ORBIS front attachments, and a solid chassis with high-traction and ground-protecting running gear. In addition, the JAGUAR 1000 features the latest generation of assistance systems and user-oriented digital solutions, including the new NUTRIMETER. Combined with one of the quietest cabs on the market and optional joystick steering, the overall concept of this internationally award-winning series delivers maximum performance, uncompromising comfort, and groundbreaking overall efficiency.

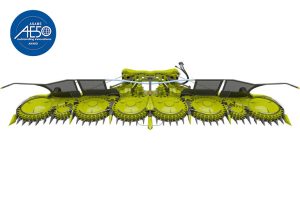

ORBIS 10500: 14 rows with uncompromising ground contour following for the harvest

ORBIS 10500: 14 rows with uncompromising ground contour following for the harvest

The ASABE jury highlighted the ORBIS 10500 in particular for its sophisticated engineering and its contribution to increasing overall harvesting efficiency. The row-independent corn header with a working width of 10.50 m (14 rows with 75 cm row spacing) operates using an independent variable drive of the knife and transport discs as well as the feed drums for optimum chopping quality in all harvesting conditions and lengths of cut. The operator can conveniently set the speeds of the crop flow components during harvesting in automatic mode to the length of cut and driving speeds from the cab. AUTO CONTOUR and actively controlled stabiliser wheels enable quick and smooth adjustments to uneven ground and ensure that the ideal working height is always maintained regardless of the topography and driving speed. Thanks to the integrated automatic transport protection and transport chassis, safe and legal road transport is possible with an external width of less than 3.30 m without long set-up times.